Billions of Yeast Cells, One Delicious Pint

The science of brewing beer

Image credit: Unsplash

By Laura Elizabeth Palermo

June 10, 2022

There's a weird, pulsing, single-chambered heartbeat thump noise in our basement. Forty-eight beats per minute, steady as a metronome. I’ve checked the water heater and the HVAC. No homeowner nightmares so far. The thump sounds from behind a closed door. I ease it open. It’s in this room; it has to be. It’s loudest here. Vigorous thumping emanates from a freezer.

“David,” I say to my husband, “The freezer’s thumping. The freezer with the car magnets on it? Is that normal?”

“It’s alive,” he says, deadpan.

I married an award-winning homebrewer. He employs specialized yeast to eat sugars, thump out carbon dioxide, and belch ethanol to brew beer. From my first thumping basement encounter, I learned that fermenting yeast pumps carbon dioxide through a blow-off tube with a noise like a strange heartbeat. I’ve learned a lot more since.

After years of pandemic hyper-focus on a pathogenic RNA virus, it’s a relief to spend time with beneficial microbes. It takes an initial investment of roughly 5 billion yeast cells to produce 1 pint of beer. At that rate, the tremendous number of yeast cells in commercial brewing and homebrewing looms unfathomably large. But science has shifted our intimacy with yeast genomes to a molecular scale.

To produce a 15-gallon batch of homebrew, clinical pharmacist and homebrewer Joe Rafferty begins with the end in mind. He thinks about what he wants in his beer glass. Rafferty says, “When I’m picking yeast, I have to factor in several properties, attenuation being one — what percentage of the available sugars is it going to consume?”

The degree of flocculation, how much yeast clumps together, influences beer clarity. Highly flocculent yeast makes brilliantly clear, sparkling lager, while lower flocculation contributes to hazy beers’ cloudy appearance. Alcohol production and tolerance feature in beer making, too. Rafferty notes, “If I’m making my wife’s 10% big stout that she loves every winter, I need to make sure I pick a yeast that can handle alcohol exposure that high.”

Turn and face the strain

Specialized fermentation companies form an essential, substantial piece of the multibillion-dollar brewing industry. Brewers can select yeasts from multinational, long-standing behemoth organizations like Lesaffre, headquartered in Lille, France, and community-oriented companies like White Labs, based in San Diego. Adventurers might try a strain from yeast crowd-sourcing establishment Bootleg Biology in Nashville, Tennessee.

Marc-André Lachance (right) and colleague William Thomas Starmer (left) process yeast samples collected during field research. Image credit: Marc-André Lachance.

Brewing yeasts’ properties originated from natural traits of wild yeasts. Through modern genetic analysis and engineering, brewers know intimately how modern beer yeasts function, down to genes that cause cell processes to work better or worse for brewing — for example, the genes that enable yeasts to produce phenolic off-flavor, or POF.

Biologist Marc-André Lachance of Western Ontario University says many yeast strains convert compounds in barley into acids, like cinnamic acid, which yeasts decarboxylate and transform into phenols. Lachance translates biochemistry to beer: “It tastes of burnt rubber.”

While some beer styles, like Belgian beers, intentionally include phenolics, others avoid them. “So, if you have a strain of Saccharomyces that is POF-negative,” meaning it is unable to produce phenols, “then your beer will not have that flavor,” says Lachance. Omega Yeast Labs in Chicago markets the Bananza and Sundew strains, engineered with the gene-editing tool CRISPR, as POF-negative selections.

Biochemist Chris White, who founded fermentation company White Labs in 1995, says beer drinkers are sometimes surprised when they learn the yeast in a craft beer was genetically modified. Yeast companies like White Labs sell and bank hundreds of strains. But mainstream beer brewing leans heavily on just two yeast species, Saccharomyces cerevisiae for ales and Saccharomyces pastorianus for lagers. Specialty brewing yeast strains represent a tiny subset of yeasts in the world, says JoAnne Carilli-Stevenson, the head of business development at White Labs.

In a 2016 paper in Cell, White and coauthors analyzed over 150 S. cerevisiae strains — different versions of the same species — to uncover their evolutionary history and humans’ role in it. White learned that modern brewing yeasts evolved from a handful of domesticated ancestors. Domesticated yeasts carry clear genetic markers that distinguish them from wild strains.

Saccharomyces can produce over 300 ester flavor profiles, says Carilli-Stevenson. She elaborates, “Belgian ale is not Trappist is not lager, and each of them have their own personalities and uniqueness.” Hefeweizen strains generate copious amounts of isoamyl acetate, which has a banana-pear flavor like Juicy Fruit gum. Other strains like German lager yeast excel because they work “clean” — they make fewer flavor molecules on their own, so ingredients like hops and malt shine.

Strain 34/70, from Weihenstephan, Germany, represents just one strain of S. pastorianus. Fermentation companies offer proprietary versions of popular strains like this lager yeast, careful not to impinge on others’ intellectual property or brewing identity. German lager yeasts established a solid partnership with human brewers as far back as the 15th century and remain hugely popular today. White Labs’ German lager yeast WLP830, which homebrewers consider equivalent to 34/70, is the company’s best-selling lager yeast. Carilli-Stevenson notes that lagers are popular in many countries.

For a batch of pilsner, a pale lager, my husband uses yeast strain 34/70 from Fermentis, a subsidiary of Lesaffre. Rafferty uses the strain consistently, too. Many brewers describe 34/70 as a reliable workhorse. Brewer Mike Karnowski of Zebulon Artisan Ales in Weaverville, North Carolina, says, “It’s like the boring, hardworking person who shows up all the time.”

Companies like White Labs process and store hundreds of strains of pure yeast cultures at low temperatures in specialized yeast banks. Image credit: White Labs.

Another hardworking strain, multitasking Lachancea thermotolerans, brings something different to the market. Fellow yeast researchers named an entire genus after Lachance, the Western Ontario biologist, an honor he characterizes as “quite a kick.” L. thermotolerans exists in nature and is utilized in brewing. Brewers traditionally use bacteria to sour beers into face-twisting, low-pH libations. But L. thermotolerans can sour beer on its own and produce ethanol.

Brewers’ quests for hardworking, ethanol-pumping yeasts played an enormous role in yeasts’ evolution — accidentally and intentionally. Lachance elaborates on brewing yeasts’ evolution. “The wise people in those Stone Age populations knew that if you take what’s at the bottom of a good beer and you use that when you start your next beer, your next beer is going to taste better,” he says. The earliest brewers knew nothing of microbes, first documented with microscopes in the 1600s, millennia after the first beer. Lachance notes that early brewers blended many different strains of Saccharomyces, which hybridized. Human-driven fermentations provided immense selection pressures, as each brew batch generates trillions of yeast cells. “It’s been happening in the wine industry, it’s been happening in the bread industry, it’s been happening in the beer industry,” Lachance concludes. “And in the last hundred years, we’ve been doing it knowingly.”

Laboratory science and industry shape yeast strains via genetic modification. “Yeast can make many things through genetic modification,” explains White. “This has been very important for human medicine.” Genetically modified yeasts have also made it possible for fuel ethanol to become much more cost-effective, he adds. One yeast strain works particularly well as a research tool to study mitosis. Another strain helps scientists better investigate transmembrane proteins. Synthetic biology involving yeast cells stripped to their fundamental parts allows researchers to craft customized cancer treatments and potentially therapeutic proteins. Microbe diversity offers humans a wealth of choices — in the lab and at the bar.

Putting it all together

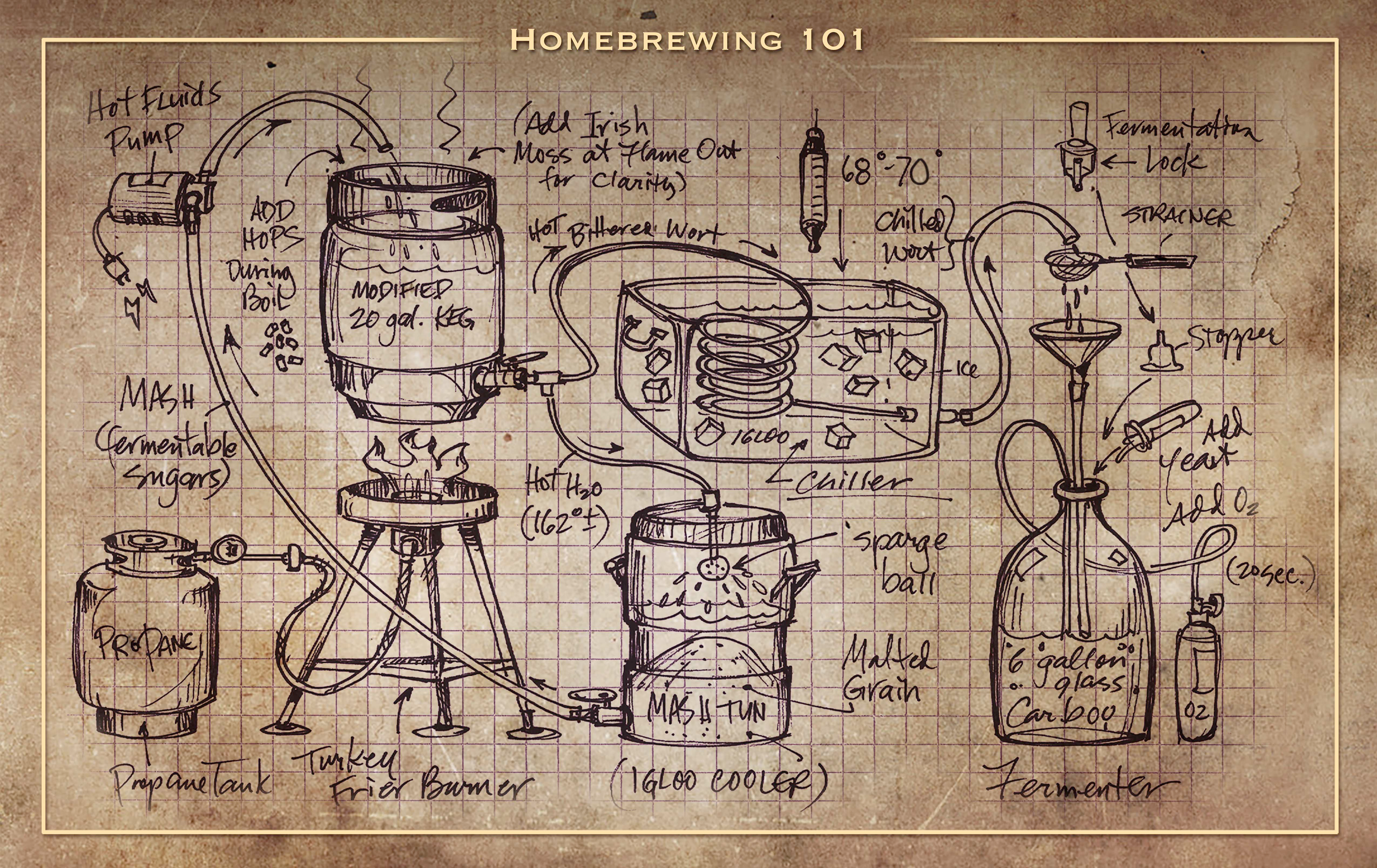

Beer at a bar starts as wort, the liquid medium that yeast ferments to make beer. Wort comes from mashing — when brewers combine water and grains. An old brewing adage describes the process succinctly: The brewer makes the wort; the yeast makes the beer. After hours of planning and prepping, pitching yeast into wort happens quickly.

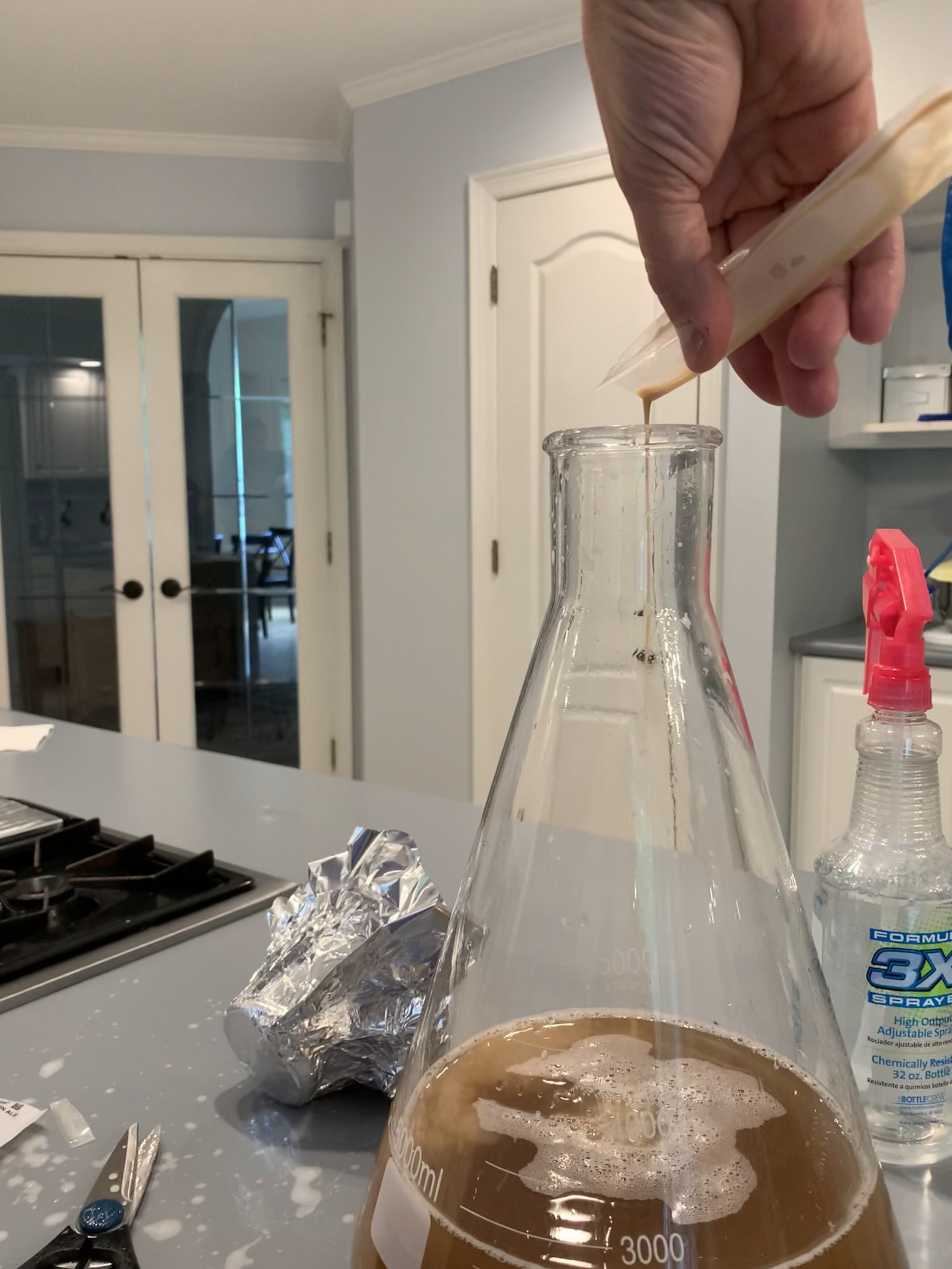

On brew day in our basement, my husband David’s wort perfumes the entire house to slight sweetness, like warm honeyed bread. I assist in rehydrating dry 34/70 yeast cells in a sterilized measuring cup. They smell tangy and musty after two minutes’ immersion in warm water. Tiny flecks of rehydrating yeast globules float down through cloudy water like snowfall without wind. A short time later, David pours frothing yeast unceremoniously into a conical fermentor near-full of wort. He hefts the fermentor into the modified freezer with the car magnets. Making beer is the yeast’s job now.

Fermentation

During his early studies in microbiology, Lachance fell in love with yeast after hearing a lecturer speak about fungi. “That was it. I really thought they were cool, and I already knew a little bit about making bread. The smell of fermenting yeast to me — that was like magic then.” He reflects on five decades in the field and says, “It still is like magic.”

Part of the magic of yeast cells is that they make energy molecules — adenosine triphosphates, or ATPs — in two ways. When oxygen is available, yeasts can perform aerobic cellular respiration. But when oxygen supply is depleted, which happens in a fermentor of wort, yeasts can ferment. Yeasts’ two cellular energy-making processes, respiration and fermentation, begin the same way, by breaking apart a glucose sugar molecule. Breaking apart the sugar molecule is called glycolysis (“glycol” means sugar, and “lysis” means to break). Yeasts need molecules to accept the electrons they release during glycolysis. The biochemical cycle of making these acceptor molecules initially releases carbon dioxide (beer bubbles!) and ultimately produces ethyl alcohol (beer buzz!) as waste. It’s waste for the yeasts but a multibillion-dollar industry for humans.

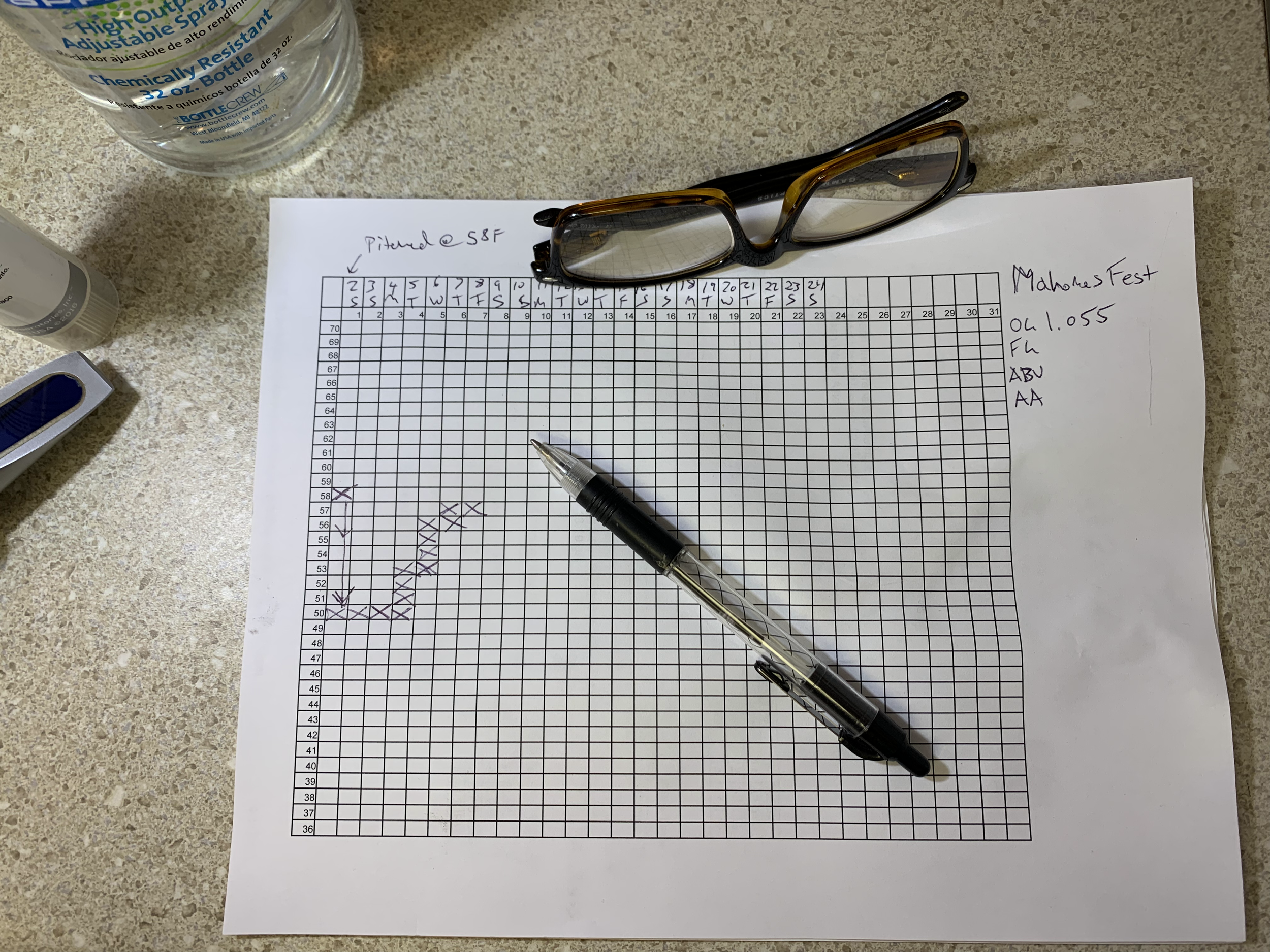

Rafferty, the homebrewer, likens fermenting yeasts to toddlers who “make this giant mess.” Many chemicals, some flavorful and others undesirable, arise during respiration and fermentation. But given time, yeasts can “come back around and clean everything up and get some of [their] byproducts out of the way,” explains Rafferty. After a thumping-good, aromatic 34/70 fermentation, “then you need time to lager,” he says.

Beer is stored at nearly freezing temperatures during lagering, hovering around 32 to 36 degrees Fahrenheit. With lagers, “You need patience,” says Rafferty. Lagering causes yeast and proteins to drop out of suspension. Faster alternatives to lagering include fining and filtering, which also clarify beer. At Zebulon, Karnowski bottle-conditions some beers, feeding yeast just the right amount of sugar in the bottle to carbonate the beverage. But not enough to explode the bottle. He’s refashioned a horse syringe into a yeast gun to inoculate bottles that need more carbonation.

Imbibing

Drinking a home-brewed beer means consuming residual yeast, even in the clearest lager. What’s in the glass represents a partnership of human and microbe, science, and artistry.

Of his lifetime of work in yeast science, Lachance says, “One of the drivers for me is very emotional, very aesthetic, as opposed to scientific. Of course, the science is great too, but the science part is harder. It requires more intellectual effort.” He likens the artistic aspect of his work to relaxing into a good brew. “You do it partly for the taste, but also you do it for the buzz. Doing science is a great buzz.”

White, a biochemist first and homebrewer second, also acknowledges the blend of disciplines in beer making. “There is a lot of art needed in brewing,” he says. “I had to learn that. Most people that start homebrewing have to do the opposite; they have to learn more about the science behind brewing. The more a homebrewer learns about science, the better beer they will be able to make.”

Twenty-one days after pitching, the thumping, fermenting 34/70 lager yeast has fallen silent in our basement. David slowly releases yeast-beer slurry from the bottom of the conical fermenter into a mason jar. The tan, creamy, mingled yeast and beer smell slightly sour. Everything from the jar to his gloves is sanitized to keep the culture as pure as possible. He recaptures 1 liter. The second generation of the strain will make Vienna lager. The third, Oktoberfest. This colony will live with us for a spell longer, about three yeast generations, which fit into about 0.33% of the span of one human generation. Cheers.

Laura Elizabeth Palermo

Laura Palermo is an award-winning STEM educator with experience in informal science institutions, K-12 classrooms, and online learning. She is currently pursuing a Graduate Certificate in Science Writing from Johns Hopkins University. With her undergraduate degree from Duke University and master’s degree from UNC Chapel Hill, she uniquely appreciates and agonizes over one of the greatest sports rivalries of all time. She aims to promote scientific literacy and to inspire learners of all ages.